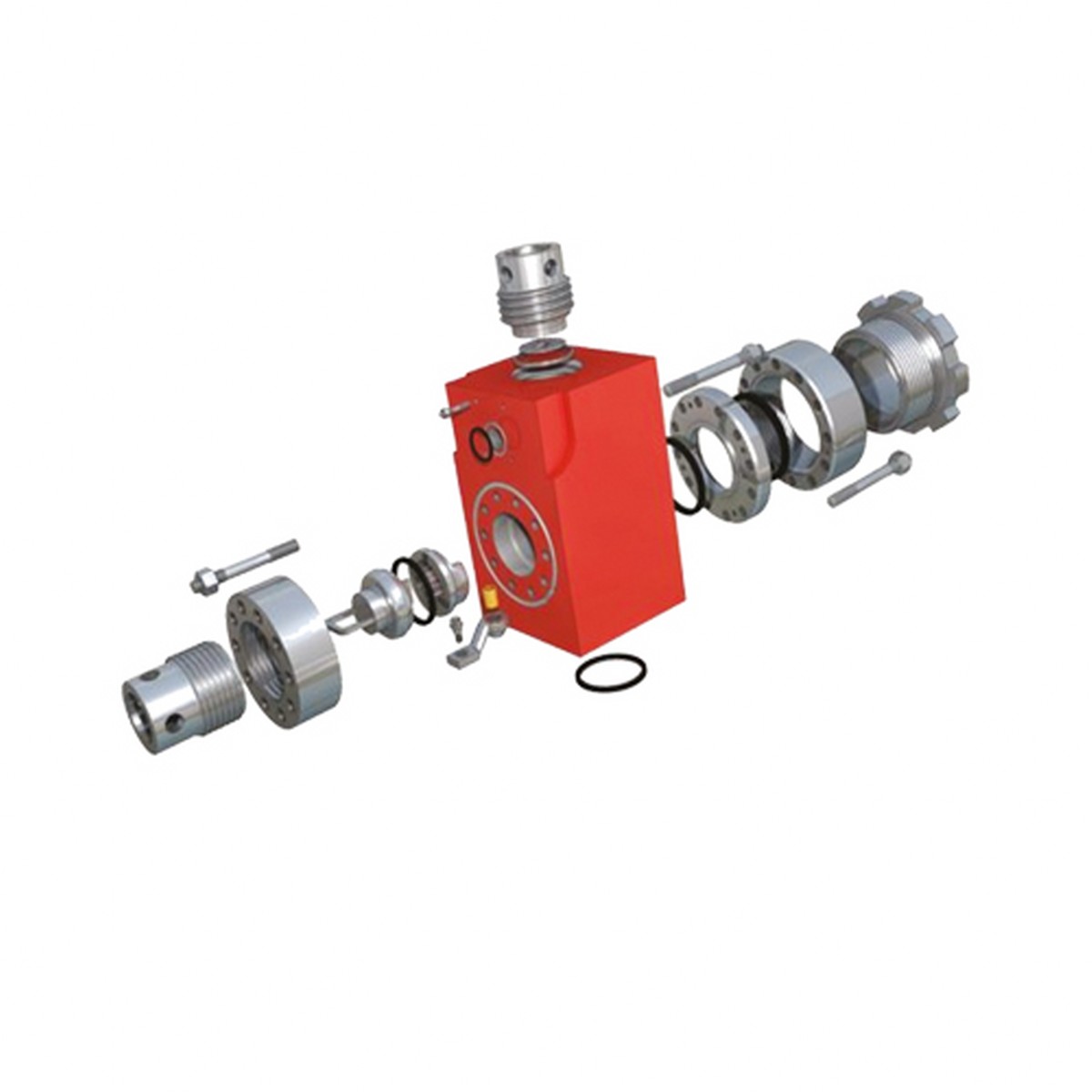

Centrifugal Slurry Pump Parts

The slurry pump wetted parts include impeller, liner, throatbush, frame plate liner insert, casing etc., The slurry pump parts are very easily worn-out components because they work under longtime impact of abrasive and corrosive slurries in the high speed.